|

| Prof. Joseph H. Saleh |

A recently published paper by Prof. Joseph Homer Saleh and his research team is challenging stakeholders in the rotorcraft industry to recommit to a more robust safety culture for helicopter maintenance and inspection procedures.

Published Feb, 1 in PLOS-One, “Maintenance and Inspection as Risk Factors in Helicopter Accidents: Analysis and Recommendations” examines the association of maintenance and inspection with helicopter accidents from both an epidemiological and a physics-of-failure perspective.

|

| Archana Tikayat Ray BS AE '18 (now a graduate student in the ASDL ) |

While helicopters are extremely effective for a growing number of civilian and military applications, it was clear to Saleh and his co-authors, Archana Tikayat Ray, Katherine Zhang, and Jared Churchwell that their failures needed to be examined more closely. Every year in the U.S. there are around 140 helicopter accidents, with an eerily consistent number of fatal accidents of about 22 crashes per year for the last decade. The overall fatality rate in helicopter crashes is 17 times greater than that of automobile accidents.

|

| Katherine Zhang BS AE '18 |

To tackle this, they had to first appreciate the uniqueness of the vehicle, Saleh pointed out.

“The fundamental feature of a helicopter design, a rotating wing, enables a host of new flight regimes that go far beyond the reach of fixed-wings airplanes,” Saleh said.

“By the same token, this fundamental feature raises a host of design and operational challenges related to the vibrating nature of the craft and the heightened risk of wear-out of its components. As a result, maintenance and inspection of helicopters are particularly crucial for the continued airworthiness and operation of these machines.”

Identifying the Temporal Signature of Maintenance Errors

|

| Jared Churchwell BS AE '18 |

After examining 10 years worth of helicopter accident data, the team noticed a significant cluster of accidents occurred immediately following inspection and maintenance. One stand-out data point: 21% of all accidents occurred within the first 10 flight-hours after maintenance and inspection; the majority of which occurred within the first couple of flight-hours. Following this cluster, the trend decreased and then leveled off after 60 hours of flight.

Saleh’s team used this unusual temporal pattern as a prompt to examine several hundred NTSB helicopter accident reports; they found that 14% of all helicopter accidents were directly caused by faulty or incomplete maintenance. Another 15% were undetermined.

Having identified how many crashes were maintenance-related, the researchers looked to see how long it took those crashes to occur. They were struck by two findings:

-

Many maintenance errors turned into accidents shortly after maintenance was performed: 34% within the first 10 flight-hours; the first quartile of all such accidents occurred within the first five flight-hours;

-

Many maintenance errors took longer to transform into accidents: 50% occurred after 20 flight-hours; the last quartile of all such accidents occurred after 60 flight-hours.

Increasingly, the picture emerging from their data was one of a pathogen – in the form of poor or unperformed maintenance/inspection – that transitioned into an accident after incubation periods of varying lengths.

“These are maintenance errors that are unforgiving and offer little or no grace period,” Saleh noted. “But this transition can also occur over longer time periods of flight-hours with maintenance errors slowly metamorphosing into accidents.”

Classification and Prevalence of Helicopter Maintenance Errors

|

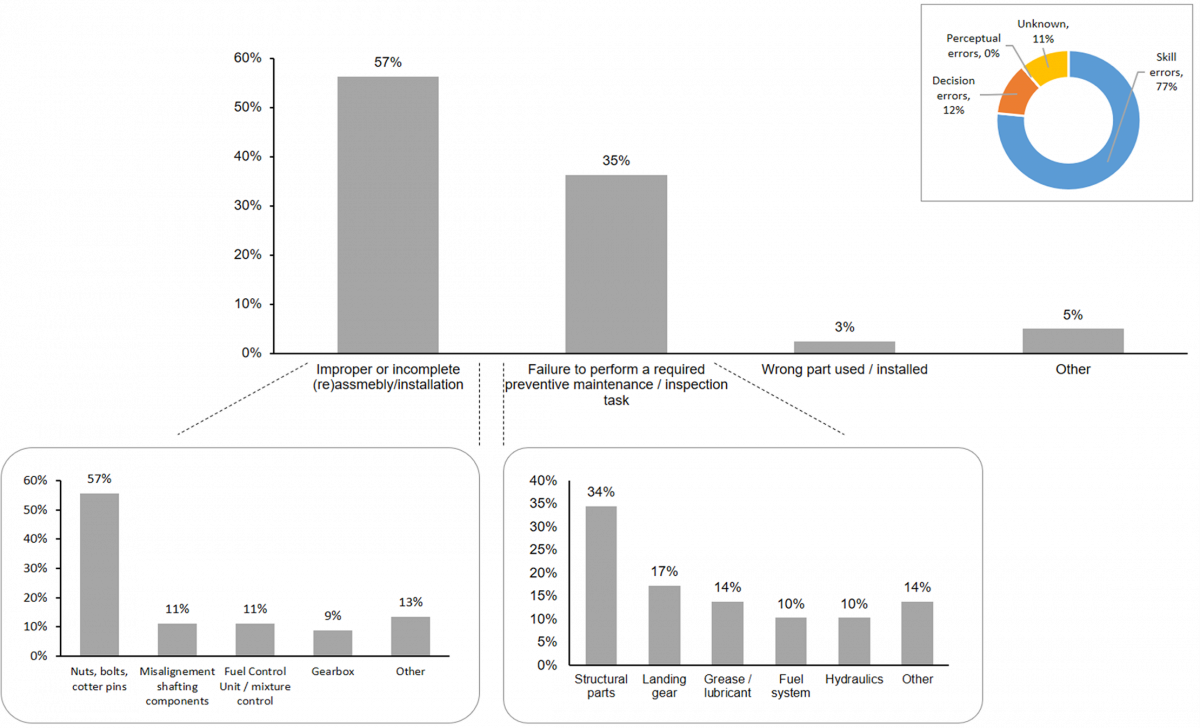

| Classification and prevalence of helicopter maintenance errors. |

To further identify the root causes of helicopter maintenance failures, Saleh's team examined six case studies in which maintenance was a leading cause of the accident. Each case identified a different failure mechanism that the team analyzed at different levels - from the organizational shortcomings in the causal chain leading up to the accident to the technical immediate causal factor precipitating the accident.

This methodological approach of selected case studies, known as a “case series” in medical and epidemiological research, offered some advantages and a few weaknesses.

"One important advantage is that it enables an in-depth examination of the etiology of a small set of similar disease cases or accidents, as the team has used it in their work," Saleh pointed out.

"Case series are also good starting points for further analytical investigations."

As an example, Saleh cited a 1981 case series that examined 11 cases of patients who exhibited “Pneumocystis carinii pneumonia," a term that was applied to early cases of HIV/AIDS. The series led to a proliferation of analytical studies that further investigated this spectrum of conditions.

"But case series also have some limitations," Saleh said. "Studies that account for 'numerator (count) data' only, and without a measure of exposure or 'denominator data,' cannot provide a ranking of most risk-prone areas and pressing safety issues to which attention and re-sources ought to be directed."

Beyond their case series, the team identified across the entirety of maintenance-related helicopter accidents, several recurring failure mechanisms, and they pin-pointed the specific maintenance tasks and components on the helicopter that played the role of accident pathogen injection.

The team found that 57% of all such cases were due to improper or incomplete re-assembly or installation. And within this category, the incorrect torquing of the B-nut and incomplete assembly of critical linkages were the most prevalent maintenance errors (the B-nut is standard terminology for nuts used to connect fluid lines. It is a simple component, but it provides a critical function as a reliable seal in plumbing systems on aircraft and rotorcraft).

Recommendations |

|

Based on their findings, the team proposed a set of preliminary recommendations that derive from the safety principle of defense-in-depth—the notion that multiple lines of defenses or safety barriers should placed along potential accident sequences, and that safety should not rely on a single defensive element. The recommendations included common-sense interventions, such as providing better training and certification of maintainers, especially when handling the critical hotspots conducive to errors the researchers identified. The researchers also emphasized the importance of nurturing a more robust safety culture when maintaining and inspecting helicopters. "This can manifest itself in different ways," Saleh said. "For example, by careful inspection and quality assurance of all maintenance work, by isolating excessive flight pressure from maintainers and carefully manage their workload, and by ensuring that maintenance work is executed in compliance with federal regulations and manufacturers’ maintenance plans. Lack of compliance with these requirements and service bulletins was found as a recurring factor in many of the maintenance-related accidents." The researchers concluded with a more practical, and directly operationalizable recommendation, that the Federal Aviation Administration (FAA) establish a multi-stakeholder taskforce, which would include helicopter manufacturers, operators, pilots, and maintenance personnel to bring their collective wisdom to bear on these issues and devise effective safety interventions to address this disquieting problem. "This is a low-handing fruit for rotorcraft safety improvement, and the objective of zero maintenance-related accidents is achievable when the collective will of the stakeholders in this community is marshaled in this direction," Saleh said. |