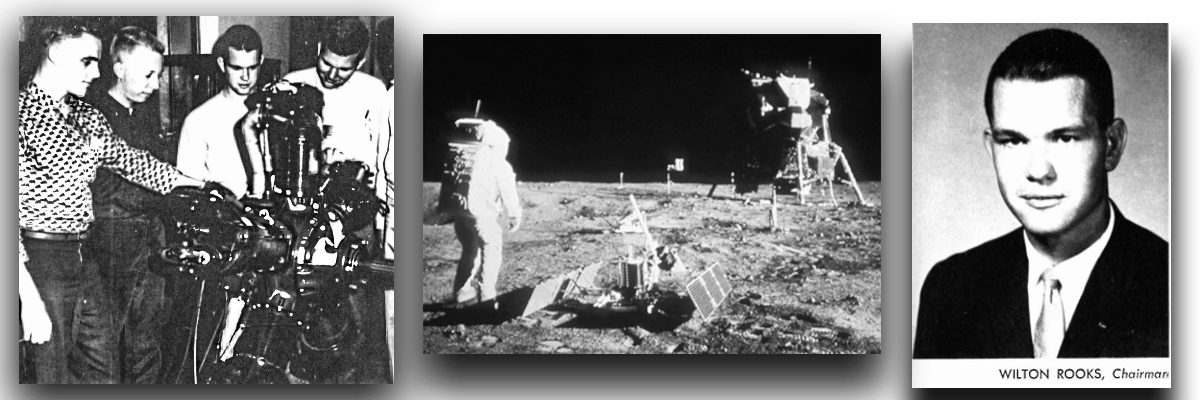

It was a different time. Wilton Rooks' memories of the Apollo program come from a very different time in our country's history. It was also a very different time to be studying aerospace engineering at Georgia tech, as the above photos illustrate. Left, Rooks and his fellow students working on an engine. Right, Rooks' yearbook photo from Georgia Tech. If you worked on the Apollo mission or have an interesting story about our country's pursuit of space exploration, send it to us at communications@ae.gatech.edu

|

|

Wilton Rooks AE '62 |

There was a lot to motivate them.

Sputnik had already been launched, and, in the ensuing years, the ‘space race’ with Russia had heated up. NASA had been given a larger role due to difficulties experienced by the military organizations in launching rockets. Repeated launch failures by the US increased the number of challenging space-related jobs that were being developed.

There was a concerted effort between the military and NASA to cooperate in this new space venture; military personnel with relevant background were being assigned to work as NASA engineers. It was in this hectic time period that I had the pleasure of working on the largest and the smallest rocket engines in the Apollo program. These are my recollections:

By the time I graduated from Georgia Tech with master's degree in aerospace engineering, it was 1962. The Air Force had already sent me orders to report to the Arnold Engineering Center in Tullahoma Tennessee. While my Air Force assignment was consistent with my education -- not to mention the 3-year Air Force obligation I had agreed to -- I was curious about other things. When NASA came on the Tech campus to conduct interviews, I decided to talk to them -- for future reference.

My discussion with the NASA recruiters was so positive that they indicated that getting my Air Force orders changed would not be a problem. Within a matter of days, those new orders were in front of me: report to the Lewis Research Center, the NASA facility in Cleveland, Ohio.

At Lewis I was assigned to the trajectory analysis team: defining a route to the Moon that would require the least amount of energy, i.e. fuel. In trajectory analysis terms, this was the Hohmann Transfer. It was exciting. Every night there were analog computer runs that we analyzed to identify the best way to get a given payload into lunar orbit using the least amount of fuel. The effort resulted in multiple tables of results and reports that were added to the volumes of data being developed at several NASA centers-- all of it to feed into decisions regarding how best to reach the moon. This was before President Kennedy’s famous speech with the commitment to successfully land astronauts on the moon – and return them.

|

|

| Top: F-1 Engine Bottom: F-1 injector plate showing circular and radial baffles and liquid oxygen/ RP-1 injector orifices. |

Saturn program known as the S-IV-B stage - a liquid hydrogen, liquid oxygen propulsion rocket. Recognizing that these two propellants needed to be better controlled, NASA transferred the S-IV-B stage management from Huntsville to Lewis for further research. As a part of that transition, the Huntsville S-IV-B program management team came to Lewis to transfer status and technical details. I part of the Lewis-based team that worked with them. One day, when I was talking to my Huntsville colleagues about how hard it was to survive on an Air Force salary ($222.00 a month -- with no medical or PX facility for shopping), they made the comment that they had a desk for me in Huntsville if I could get the Air Force to transfer me. With a wife and very small child, that sounded pretty appealing, especially since the job function involved propulsion issues with the Saturn program.

Not long after, we moved to Huntsville where I officially joined the program management team for the Saturn V, F-1 rocket engine.

Early in the assignment, I was aware that the F-1 engine (largest ever built – still) was having combustion instability problems when tested at Edwards Air Force Base. The F-1 burned a combination of liquid oxygen and RP-1 (basically high grade kerosene). Instability is a problem since it results in very high heat transfer to the side of the combustion chamber. Eventually it burns through and explodes. The cooling mechanism for the combustion chamber, throat and exit cone was based on the RP-1 circulating around the engine and returning to the injector plate. But the design depended on a smooth burning process rather than turbulent burning in the combustion chamber. There was considerable experience with the combustion process of these two propellants in previous engines, but not with an engine the size of the F-1. Without a stable F-1 there would be no Apollo program.

That's when a simple scheduling conflict gave me an unexpected opportunity to push forward. A top propulsion expert in our team was unable to attend the Combustion Instability conference on Nantucket Island.I was asked to attend in his stead. This put me in touch with the leaders in the field on this new problem.

Subsequently, NASA organized an Combustion Instability Ad Hoc Committee to solve the F-1 problem. Another engineer from our team and I were assigned to represent Huntsville on that committee. A small group of engineers from NASA and Princeton University were sent to Rocketdyne in California to work at the test facility in the Santa Susana mountains for about 3 months. Other engineers were addressing the issue at different locations.

I was given the task of working with a test engine that was a slice of a full-scale engine; it differed only in that it had transparent sides that allowed us to film the combustion process. We deliberately installed a ‘bomb’ in the chamber so as to trigger instability. With a high-speed camera (5,000 frames per second), we were able to watch what happens after the combustion process becomes unstable. Obviously the transparent sides did not last long during the test, but they were there long enough for us to get films that we could analyze, one frame at the time.

Through this technique and others, design changes were made to the F-1 injector plate and baffles were placed in the combustion chamber. The injector design changes made the combustion process less likely to become unstable. And if it did go unstable the baffles would dampen the high pressure waves.

Thorough testing of the redesigned F-1 further validated the redesign efforts. A hallmark of the success of the changes is that there were no incidents of failure of an Apollo launch due to the F-1 engine not performing. The five engines reliably produced a total of 7.5 million pounds of thrust, lifting the 7.5 million pounds of weight from the launch pad.

Later, I was able to work on the small attitude control engines that control the yaw, pitch and roll of the spacecraft when in orbit or on the trajectory to the moon. The propellant used in these were hypergolic, burning as soon as they came in contact with each other. Their operation was quite different and simpler than the F-1.