Bragging Rights and Old Friends. Joining team ColumBuzz and Buzz^2 were seven AE alums who flew in to volunteer. They are seen here with their DBF alma mater. (l to r) Matthew Warren, Vy Tran, Rafiya Tasnim (BSAE '17), Daniel Bae, Gowtham Venkatachalam, Adam Thomas (BSAE '16), Ogun Kargin, Thomas Harrington (MSAE '18), Pranav Krishnamurthy, Parth Kumar, Frank Kozel, Tom Neuman (BSAE '13), Micaiah Smith-Pierce, Jonathan Paravano, Mark Lau, Daniel Sagan, Carl Johnson, David Moroniti, Viktor "Vik" Hromyk (BSAE '16), David Gaitan (BSAE '15) | View photos | Watch ColumBuzz and Buzz^2 Competition Videos.

For the fifth year in a row, two aircraft designed by students from AE's Aerospace Systems Design Lab (ASDL) have landed in the top two of the Society of Automotive Engineers (SAE) Aero Design East competition, held March 8 – 10 in Fort Worth, Texas.

Placing first overall in the Advanced Class was ColumBuzz, a blended wing body aircraft that bested a field of 21 competitors.

Placing second overall in the Micro Class was Buzz^2, a five-pound unmanned aerial vehicle (UAV).

There was a lot of wind beneath their wings on competition day: direct crosswinds of up to 30 miles-per-hour made the competition that much more challenging.

"Crosswinds, or strong wind gusts, are the biggest challenge during take-off and landing because the airplane has to be positioned sideways to be able to fly or land in a straight line," said grad student Matthew Warren, who piloted both vehicles.

The Advanced Class Competition

The 21 teams in the advanced class were tasked with colonizing Mars.

|

| Frank Kozel overseeing the technical inspection of ColumBuzz |

Teams had to build an aircraft capable of carrying a payload that included three autonomous gliders, each carrying ping-pong balls that represented Mars colonizers (humans). Taking a cue from history, Team ColumBuzz named their gliders three other famous explorers: the Niña, the Pinta, and the Santa Maria.

“The number of teams attempting advanced class was larger than expected," said Frank Kozel, ColumBuzz's chief engineer. "We believed the complexity of the mission would push teams to compete in regular class, rather than advanced.”

Like that of a real colonization mission, the ColumBuzz aircraft had to deploy supplies and habitats before dropping the colonizers. “Habitats” and “supplies” were represented with Nerf Sports Vortex Aero Howlers and half-liter water bottles, respectively. Both were dropped onto a target from between 50 and 100 feet in the air. The gliders, fully-loaded with ping-pong balls, weighed less than nine ounces.

“Our team never had the opportunity to test the gliders in high crosswind conditions, so we were unsure of how they would preform" said Kozel.

"The many hours of hard work by the DBF team went into the construction of the aircraft, and without this contribution and attention to detail, any single point failure would have had catastrophic results in the high winds," said Kozel.

The Micro-Class Competition

The challenge for the Buzz^2 team was to build a UAV that was light-weight, quick to assemble, and capable of flying a 1000-foot loop. The official specs tasked the team with delivering the unassembled vehicle in a box measuring 12.125 inches by 3.625 inches by 13.875 inches.

|

| Carl Johnson |

“Our team had one of the fastest assembly times at the competition” said ASDL research faculty Carl Johnson, the DBF team coordinator.

All teams were given up to three minutes to assemble their vehicles.

“We assembled the plane in 20.6 seconds," said the micro class chief engineer Ogun Kargin. "We knew we had to get the time under two minutes to avoid being penalized. We practiced about 20 times to get it just right."

"The assembly may look simple, but it took a lot of aligning and assembly lock features for it to actually work. It took us about four months to perfect the locks and align them in such a way to keep the plane from disassembling during flight” said Kargin.

Though this is Kargin’s third year participating in the SAE micro class competition he found plenty of challenges to keep him on his toes this year.

“One of biggest differences about this year’s rules was the low-density payload requirement, which means you have a lot of volume that has to fit inside of a rather small box” said Kargin.

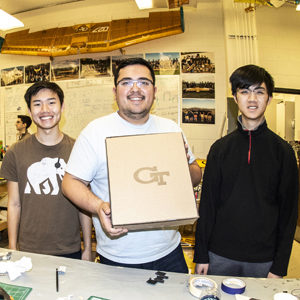

|

| Joshua Ngonico, Ogun Kargin, and Eric Tai, holding the regulation box for their entry into the micro class competition |

They were able to achieve a quick assembly time by putting the payload - PVC pipes - within the wing section rather than the conventional location - underneath the plane.

“We wanted to carry as much as we could to get a higher score," said Kargin. "We ended up using four-and-a-half out of the maximum five pipes allowable.

Buzz^2 was manufactured with the help of the DBF selective laser sensoring printer (SLS), the ASDL laser cutter, and the Yang Aero Maker Space’s foam cutter and laser cutter.

With SAE competition done, the team can now set its sites on another rite of spring: the AIAA DBF competition on April 5-7, 2019 in Tucson, Arizona. Their entry will be the BuzzFormer.

Up, Up and Away. Team ColumBuzz and Buzz^2 are seen here after taking the first and second places, respectively in the 2019 SAE Competition (l to r): Hyun Bae, Gowtham Venkatachalam, Ogun Kargin, Matthew Warren, Pranav Krishnamurthy, Parth Kumar, Frank Kozel, Micaiah Smith-Pierce, Jonathan Paravano, Mark Lau, Daniel Sagan, Carl Johnson