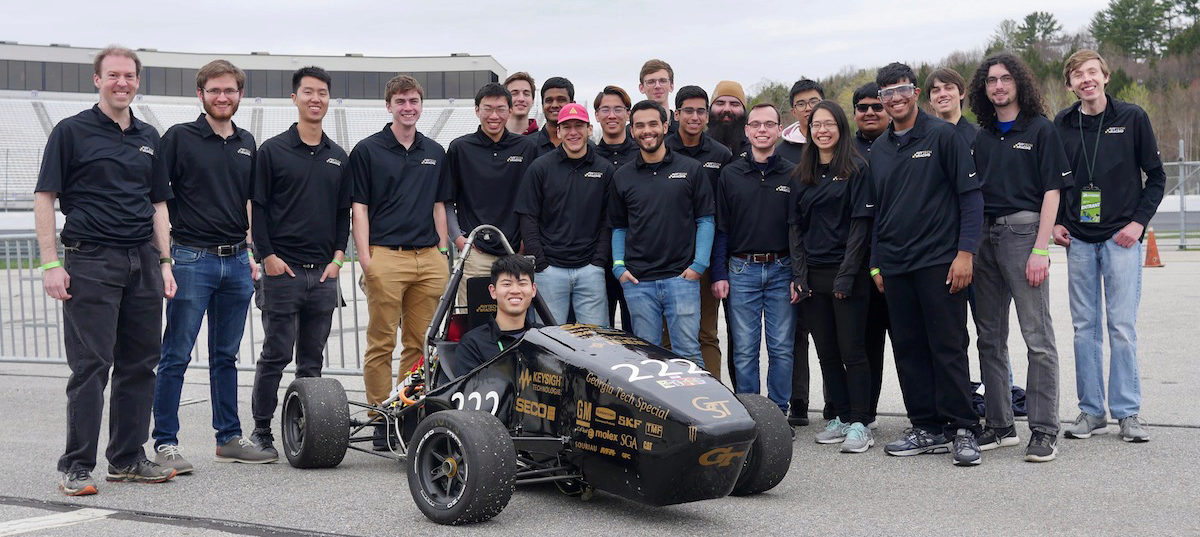

Collaboration Matters. Members of Georgia Tech's HyTech Racing Team who made it up to New Hampshire are, from left, Dr. Lukas Graber (ECE), Nathan Cheek (CS), Max Boonbandansook (IE), Dean Plaskon (EE), Aaron Hui (ME), Peter Wagstaff (CS), Jishnu Medisetti (AE), Harrison Kollias (ME), Yu (John) Xin (EE), Diego Monge (ME), Leonid Pozdneev (EE), Ajay Sukhwani (ME), Sam Gilmer (ME), Ryan Gallaway (CS), Anson Tsang (ME), Yvonne Yeh (EE), Arvind Srinivasan (CompE), Asimm Hirani (ME), Russell Sprouse (ME), Daniel Elkin (ME), and Brent Bessemer (CS)

Collaboration Matters. Members of Georgia Tech's HyTech Racing Team who made it up to New Hampshire are, from left, Dr. Lukas Graber (ECE), Nathan Cheek (CS), Max Boonbandansook (IE), Dean Plaskon (EE), Aaron Hui (ME), Peter Wagstaff (CS), Jishnu Medisetti (AE), Harrison Kollias (ME), Yu (John) Xin (EE), Diego Monge (ME), Leonid Pozdneev (EE), Ajay Sukhwani (ME), Sam Gilmer (ME), Ryan Gallaway (CS), Anson Tsang (ME), Yvonne Yeh (EE), Arvind Srinivasan (CompE), Asimm Hirani (ME), Russell Sprouse (ME), Daniel Elkin (ME), and Brent Bessemer (CS)

The Georgia Tech HyTech Racing Team bested a field of 12 electric-powered competitors to take home the first-place trophy for design at the 2019 Formula Hybrid Competition, held at the New Hampshire Speedway, April 28 to May 2.

Now closing out its thirteenth competition year, the Formula Hybrid Competition annually brings together students from around the world to identify the best-engineered and best-performing electric and hybrid open-wheel Formula racing-style vehicles.

More than a trophy, the Georgia Tech HyTech Racing team brought home some great statistics this year:

Their vehicle finished the Formula Hybrid competition with a 277-point lead over the second-place finishers, taking home 919 points out of a possible 1,000. In addition to placing first in the Autocross event with a 44.092-second run, the electrically-powered vehicle completed more than twice the number of laps of the second-place competitor in the Endurance trial, setting a new course record with its 01:15:56 track time. (The previous record was 01:25:15.) At 368 pounds, the HyTech vehicle was also the lightest one in this year's competition and only the second electric vehicle to complete a recently enhanced Endurance course.

|

|

| Ready to Ride. seated: driver Jeff Ding (ME) standing, from left: Harrison Kollias (ME), chief engineer Sam Gilmer (ME), and team president Nathan Cheek (CS) |

"Until 2014, the Endurance course was 22 kilometers, so it was much easier to finish," said team captain, Nathan Cheek. "We are one of two teams to complete the Endurance course since it was extended in length to 44 kilometers in 2014."

First place was not the only place that HyTech took. With a final time of 5.28 seconds, their vehicle easily took home the second place win in the Acceleration trial. The team's obvious attention to detail throughout the process garnered them a second place finish in the project management category as well.

HyTech Racing is an award-winning electric vehicle racing team at Georgia Tech that participates in the annual Formula Hybrid (Electric Class) and FSAE Electric competitions in Loudon, New Hampshire and Lincoln, Nebraska respectively. The team is comprised of undergrad and graduate students from the Schools of Aerospace Engineering, Mechanical Engineering, Material Science Engineering, Computer Engineering, Industrial Engineering, Electrical Engineering, Physics, and Computer Science. The 60-member team works together year-round to design fully-electric race cars at Tech's Student Competition Center - a massive complex on 14th Street.

Working on weekends and after classes, their efforts might have escaped the notice of their classmates during the school year, but their results were publicly praised by Institute leaders.

"This sort of multidisciplinary collaboration is precisely what makes Georgia Tech such an exciting place for any engineer to study, research, and learn," said Mark Costello, the William R. T. Oakes School Chair of the Aerospace Engineering School. "The experience they've had dealing with budgets, deadlines, and real-world project management issues is invaluable."

Costello's praise was echoed by his colleague:

“The work that is happening on teams like HyTech is an important part of the experiential learning here at Georgia Tech,” said Dr. Samuel Graham, Eugene C. Gwaltney, Jr. Professor and Chair of the Woodruff School of Mechanical Engineering.

Before testing the dynamic performance of the vehicle, each team must pass through a rigorous review process where working engineers - many from the automotive industry - inspect each vehicle to ensure that it meets competition rules and can be safely operated. The competition also measures the engineering behind each team’s vehicle.

Before testing the dynamic performance of the vehicle, each team must pass through a rigorous review process where working engineers - many from the automotive industry - inspect each vehicle to ensure that it meets competition rules and can be safely operated. The competition also measures the engineering behind each team’s vehicle.

In presenting their product, the Georgia Tech student engineers meticulously explained the design methodologies that enabled them to effectively use components that were far lighter than those used in previous years.

“There's an old adage in racing that goes 'more power makes you faster in the straights, losing weight makes you faster everywhere',” said Sam Gilmer (ME), HyTech Racing's chief engineer. “Being light means your tires are more efficient and you have less momentum and accelerate more quickly.”

After building a 413-pound vehicle for last year's competition, the HyTech Racing beat their own goal of 380 pounds by producing a 368-pound vehicle for the 2019 competition.

“Working with more than 60 students to engineer such a complex vehicle takes a significant amount of planning and oversight,” said Cheek (CS). “We focused this year on making a very light-weight and tightly packaged vehicle, so facilitating communication between sub-teams was critical for insuring that everything would fit together and work together.”

Cheek explained that vehicle performance is measured through a number of dynamic events, beginning with its acceleration capabilities which are measured at the 75-meter Acceleration track. After that, vehicle handling is put to the test on the Autocross course. Finally, the ability of each vehicle to run reliably is tested through the 44 km Endurance event.

Looking ahead, the HyTech Racing team plans to work iteratively, building a new vehicle with updates only to the systems that will most improve the car’s performance.

“Next year we are going to focus on making the car even lighter and better performing using data we gathered from this year's success,” said Yvonne Yeh, (ECE) incoming team president for the 19-20 school year.

Cheek agreed, adding:

“It’s important to update these vehicles methodically year-to-year. Making calculated engineering updates to specific vehicle subsystems is the best way to ensure we have plenty of testing time on our new vehicle before taking it to a competition.”