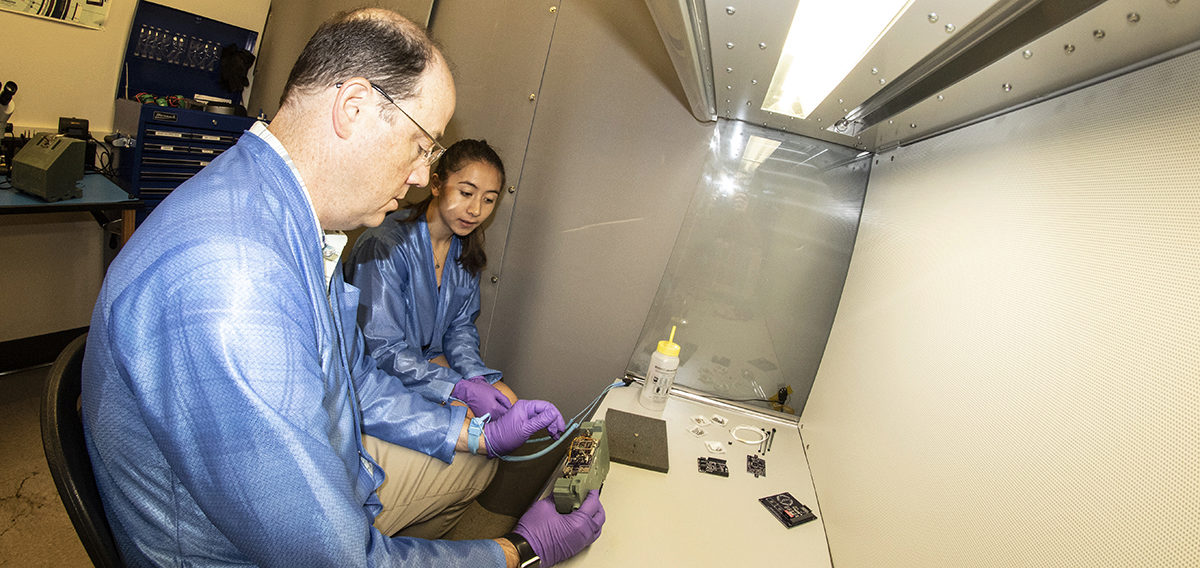

Always Improving. Prof. E. Glenn Lightsey and grad student Dawn Andrews working on one of the 3D-printed ceramic thrusters that have been approved for the BioSentinel mission.

|

| Prof. E. Glenn Lightsey |

As the world gathers to celebrate the 50th anniversary of Apollo 11's mission to the moon, AE professor E. Glenn Lightsey is marveling at another revolution - the small satellite - that is shaping the next chapter of space technology and exploration.

"Ten years ago, these CubeSats were seen as hobbies, as toys, even," Lightsey says as he picks up a shoebox-sized metal box, one of several small sats he has designed or launched over the last decade.

|

| Huge Potential in a Small Package. AE grad student Jacob Payne holds a 3U CubeSat that is similar in size to the 6U BioSentinel satellite NASA will launch in 2020. Tiny space vehicles like these are the scaffolding of next generation space travel. |

"But what we've seen is that these satellites’ capabilities have advanced and we now have a fully functional, science-quality observation platform that can perform commercial and scientific missions. For example, several well-known companies want to use small sats to provide services like ubiquitous access to the Internet. They want to launch a swarm of small sats so you can get internet access in places where there is no infrastructure - like over the ocean or where a natural disaster has taken out the infrastructure. The great thing is, we can reasonably expect these projects to happen, now, and Georgia Tech is conducting the space research that is making it happen."

As the head of the AE School's Space System Design Lab (SSDL) and the associate director of Georgia Tech's Center for Space Technology and Research (CSTAR), Lightsey is fully immersed in that research. What excites him though, is that he's not doing it alone.

"A big part of our identity, as a School and as a lab, is that we reach out -- across campus and across the world -- to build teams that are finding solutions to design challenges that have been unsolved until now. And our students are actively engaged in the process. Really, it's an exciting time to be doing this work. Each space mission that we participate in is a new adventure."

BioSentinel Mission: Exploring the Risks of Long-term Space Habitation

For Lightsey - and his students – one of these adventures is BioSentinel – a NASA mission that involves a briefcase-sized (6U) CubeSat that houses an SSDL-built thruster for deployment outside the reach of the Earth's magnetic field.

Thruster Research:

|

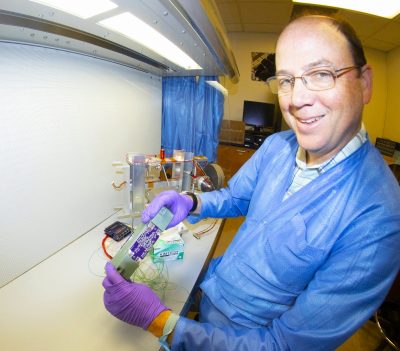

Before he'll talk about where CubeSats go, Prof. Glenn Lightsey insists on talking about how they get there. Thruster research has allowed Lightsey's CubeSats to be more maneuverable, and more capable of executing specific actions, like station-keeping and formation flying. All of this from a piece of technology that is barely larger than the average cell phone. (Lightsey is holding one in the photo, above). He is proud to tell you that it was his students who pushed this 3D-printed thruster concept from the drawing board to the launch pad. "Originally, the work on thrusters started out as an undergraduate research project.The students demonstrated that they could use a 3D-printer to make one, and people got interested in it, " he said. "We knew what propellants we wanted to use based on good design principles, and we selected valves that would work in the vacuum of space. In the end, we created a complete system - one that we eventually made for Prox-1 [the AE-built small sat that recently deployed from the Falcon Heavy]." A lot of very complex engineering went into a very simple design. "Simplicity was an advantage," he says, as he holds up a slender mint green plastic box - the thruster - that fits perfectly within the walls of an oblong metal cubesat. Compact as it is, this 3D-printed thruster is further lightened by a series of channels and chambers within that hold a very dense liquid propellant - R236. "It's chemically inert, so it's safe to work with. And it's commercially available. But the most important thing is that the propellant is dense because we have very little volume to work with," he said. "It's called a 'cold gas thruster' because it's just an isotropic expansion of gas that produces the thrust. There's no fuel and oxidizer like you have in a modern rocket engine. It works like a fire extinguisher. It doesn't generate a lot of impulse, but the delta V is sufficient for a CubeSat." |

Scheduled for launch in late 2020, the BioSentinel CubeSat will use biosensor instrumentation to gather information on the impact that solar radiation has on humans who will be involved in long-term space travel outside the Earth's magnetic field.

"On Earth, and in Low Earth Orbit (LEO), our magnetic field protects us from exposure to harmful solar flares and X-rays. Ninety percent of the sun's harmful radiation never makes it to us on the Earth’s surface because it is deflected by our planet’s magnetic field. But if we send a human mission to the moon or Mars, they don’t have strong magnetic fields like the Earth does, so the astronauts will not have the same protection from radiation. They will be directly exposed to space radiation for months," Lightsey explained.

"The purpose of NASA’s BioSentinel mission is to understand the risk of that exposure, to see how DNA is affected by long-term space exposure. And, then, to figure out, eventually, how this radiation exposure can be mitigated."

Instead of human subjects, BioSentinel will use dry yeast cells that will be rehydrated in space. The results of their exposure will be downlinked to Earth for further study.

Among other things, biologists will be be looking to see if deep space exposure leads to double strand breaks - DNA lesions which are generated by exposure to highly energetic particles known to exist in the deep space radiation environment.

The BioSentinel CubeSat that will transport this mini-laboratory into space is one of about 10 small sats that will be deployed by NASA’s Exploration Mission-1 (EM-1) that is scheduled to be launched into a lunar trajectory in late 2020.

Once deployed, one of the CubeSat's biggest challenges is sending mission-critical data back to Earth for analysis. This is where Lightsey's thruster comes in. The 3D-printed ceramic thruster that Lightsey's team built will allow BioSentinel to perform one of its most important tasks: communication.

"To communicate with the Earth, BioSentinel needs to re-orient itself while it's operating. It has to be pointed toward the Earth for the transmissions to be received," Lightsey explained.

"But when you are in interplanetary space, there are not a lot of ways to re-orient your vehicle because there's nothing to push off. Our thruster provides this maneuverability by allowing BioSentinel to exchange momentum with other parts of the spacecraft. It ejects mass - the propellant - which pushes the rest of the spacecraft in the other direction."

In 2015, when NASA was planning the BioSentinel mission, the fact that the SSDL was already developing a small, lightweight thruster made the lab's technology hard to ignore.

"They [NASA] did a market survey to see who made really small thrusters. When they found out about our thruster, they asked us to put together a concept paper for their project," he said. "And so this thruster that was designed and built by students in our lab is now helping NASA complete a mission to the moon."

Of course no mission is that quick.

For the better part of four years, Lightsey's team has undergone multiple reviews and tests that have resulted in many tweaks and outright changes to the thruster. After completing some exacting tests at NASA's Glenn Research Center in 2017, the thruster was delivered to NASA Ames Research Center last year, where it is now being integrated into the final satellite.

"We welcomed the healthy skepticism of experts," said Lightsey, himself a former NASA engineer.

"We were able to spot compatibility issues - some materials don't work well together or they don't perform well in space. And we were able to custom design systems that met the specific needs of BioSentinel. We had NASA engineers review our design and certify it. There's really an amazing amount of work that went into this very small piece of technology."

Proud but not finished.

Lunar Flashlight Mission: Surveying the Moon as a Possible Home Base

Lightsey retains a healthy amount of ambition for the next generation of miniature thrusters -- ones with more power, heat resistance, and durability. That shift is happening today, he says, thanks to new 3D-printers that are capable of printing metal thrusters.

"With metal thrusters, we can go to higher temperatures and pressures than we could with ceramic thrusters. That opens us up to different propulsion concepts, like monoprops and green propellants, whose exothermic reactions lead to greater momentum transfer. The higher that momentum transfer, the faster you can make the CubeSat move."

That larger force will come in handy for another small sat project Lightsey's team is working on with NASA for deployment on the same EM-1 flight: Lunar Flashlight.

Scheduled to be released by NASA on the same mission as BioSentinel, the Lunar Flashlight CubeSat will use a 3D-printed metal thruster to enter into an orbit of the moon. Once there, it will reflect a laser off the lunar surface and analyze the spectroscopic signal it receives to determine where ice may be located on the lunar surface.

"Scientists hypothesize that comets crashing into the surface of the moon millions of years ago left water that has remained frozen and trapped in craters," Lightsey explained.

"If we can map those locations, then we will be able to tap into that frozen water in future human exploration-- something we can use to make fuel, and, also, to help astronauts survive."

While planetary scientists devise ways of surveying the moon, Lightsey's team is working with NASA to design the thruster that will allow Lunar Flashlight to move into lunar orbit.

"This is where the idea of using a 3D-printed titanium thruster along with a monopropellant comes in. You get more energy per unit of mass from a monopropellant than you can from the cold gas thrusters," Lightsey said.

"That's why we're using metal thrusters for Lunar Flashlight. We are heating up the monoprop to about 1000 degrees centigrade which causes it to decompose, chemically, into its different constituents. This chemical reaction releases more heat than we can get from an isotropic expansion. More heat means more momentum transfer. This is what allows the CubeSat to get into lunar orbit."

The concept of 3D-printing satellite components goes further. Eventually, Lightsey predicts, the thruster and satellite will likely be 3D-printed together as a single device. The greater amount of integration will create more efficient and capable miniature satellites.

Stay tuned.

Teamwork Matters. Grad students working with Prof. E. Glenn Lightsey in the Space Systems Design Lab.