We Are Going: Georgia Tech team develops propulsion system of CubeSat onboard Artemis I.

|

| Prof. Glenn Lightsey |

All eyes will be on the sky as NASA’s Artemis I mission launches from the Kennedy Space Center in Florida. Georgia Tech David Lewis Professor of Space Systems Technology, Glenn Lightsey, and his team developed the propulsion system for the small satellite BioSentinel that will be onboard the Space Launch System (SLS) megarocket.

Artemis I is the first in a series of NASA missions that aims to return humans to the moon, including the first woman and person of color. It’s also the first integrated test of NASA’s deep space exploration systems including the Orion spacecraft. During the 42-day mission, the Orion spacecraft will travel around the moon and earth in a figure eight route, on a free return trajectory to earth. During the mission, Orion will deploy ten CubeSats, each with their own specific mission.

AE alumnus Terry Stevenson (PhDAE‘18) and Matt Sorgenfrei, both aerospace engineers at NASA Ames Research Center, worked with Lightsey to develop the propulsion system for BioSentinel. The 6U CubeSat will carry two strains of yeast to understand the impact of deep space radiation on living organisms. It is the same yeast used in bread and beer. One strain of the yeast is commonly found in nature and the other has trouble repairing DNA. “It’s about survival in space and radiation damage, specifically DNA strand breaks. We don’t know how organisms will be affected by deep space radiation beyond the earth’s orbit,” Lightsey said. According to NASA, BioSentinel will be the first long duration biology experiment to take place beyond where the space station orbits near earth. When the satellite is past earth’s protective magnetic field, scientists will begin experiments remotely, activating two strains of the yeast at different points in time during the mission. Miniature propulsion systems allow these small satellites to accomplish their missions. Since BioSentinel’s propulsion system makes the spacecraft maneuverable, they will use it to point the antenna to earth where researchers will communicate with the satellite and collect data which will be transmitted back to earth.

Origin Story:

|

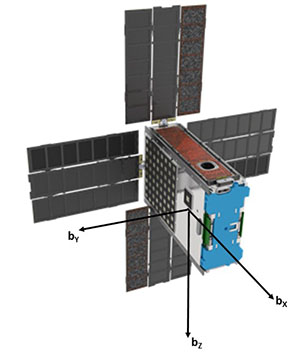

| Close up picture of the BioSentinel flight unit propulsion system |

In 2013, a couple of undergrad students working with Lightsey at the University of Texas approached him about making a maneuverable propulsion system. “If it isn’t maneuverable, you’re basically launching an inert box into space, and once it gets into orbit, it’s going to drift around like a piece of space debris, and you don’t have any control over it. So, we needed a smaller propulsion system that would make the spacecraft maneuverable, about the size of a brick. No one had built a thruster that small before,” Lightsey explained.

Lightsey’s team decided they needed to 3D print the tank and the structure of the propulsion system because additive manufacturing enables you to create complex shapes that you wouldn’t be able to manufacture using other methods. “The propulsion system is made of a material called Accura Bluestone, an additively manufactured ceramic-like resin that can be 3D-printed in a wide range of shapes and sizes. The material is space-rated, meaning that it will work in the harsh environment-temperature and vacuum-of space,” Lightsey added.

|

| Conceptual design of how the propulsion system (in blue) fits on the end of the BioSentinel |

NASA was aware that Lightsey was researching additively manufactured propulsion systems for small spacecraft and in 2015 they approached him and his team about building the propulsion system for BioSentinel. After it was delivered to NASA in 2017, the propulsion system went through a series of stringent and lengthy tests at the Glenn Research Center in Ohio and was given the green light for flight.

The work on BioSentinel’s propulsion system led to Georgia Tech Space Systems Design Laboratory’s work on the Lunar Flashlight Propulsion System, which is tentatively scheduled to launch in early 2023. This represents a more advanced propulsion system technology from BioSentinel. Lunar Flashlight requires more complex and advanced maneuvers. “We went with a monopropellant, a molecule that decomposes through a chemical process. The decomposition elicits an exothermic reaction and creates a lot of heat. The energy comes from the molecules instead of just the thermodynamic expansion of gas. We’re breaking molecules apart and releasing the energy in those molecules,” Lightsey explained. This model results in a completely different design. The 3D printing was done in metals, specifically using a laser sintered powder metal process.

Research Leads to Better Aerospace Access for Universities:

For 25 years, miniaturizing spacecraft has been a focus of Lightsey’s research because making spacecraft smaller provides more access to space, particularly for universities. “In the early 2000’s, there weren’t a lot of space missions because launching anything into space was expensive,” Lightsey asserted. “Our program at Georgia Tech is launching at least a satellite a year now, which is in part or totally built by AE students. They are getting experience in designing, building, and flying a mission, and this has just come about in the last ten years. With miniaturization, this is all possible. It is now a part of Georgia Tech’s curriculum, and students can graduate with that experience.”