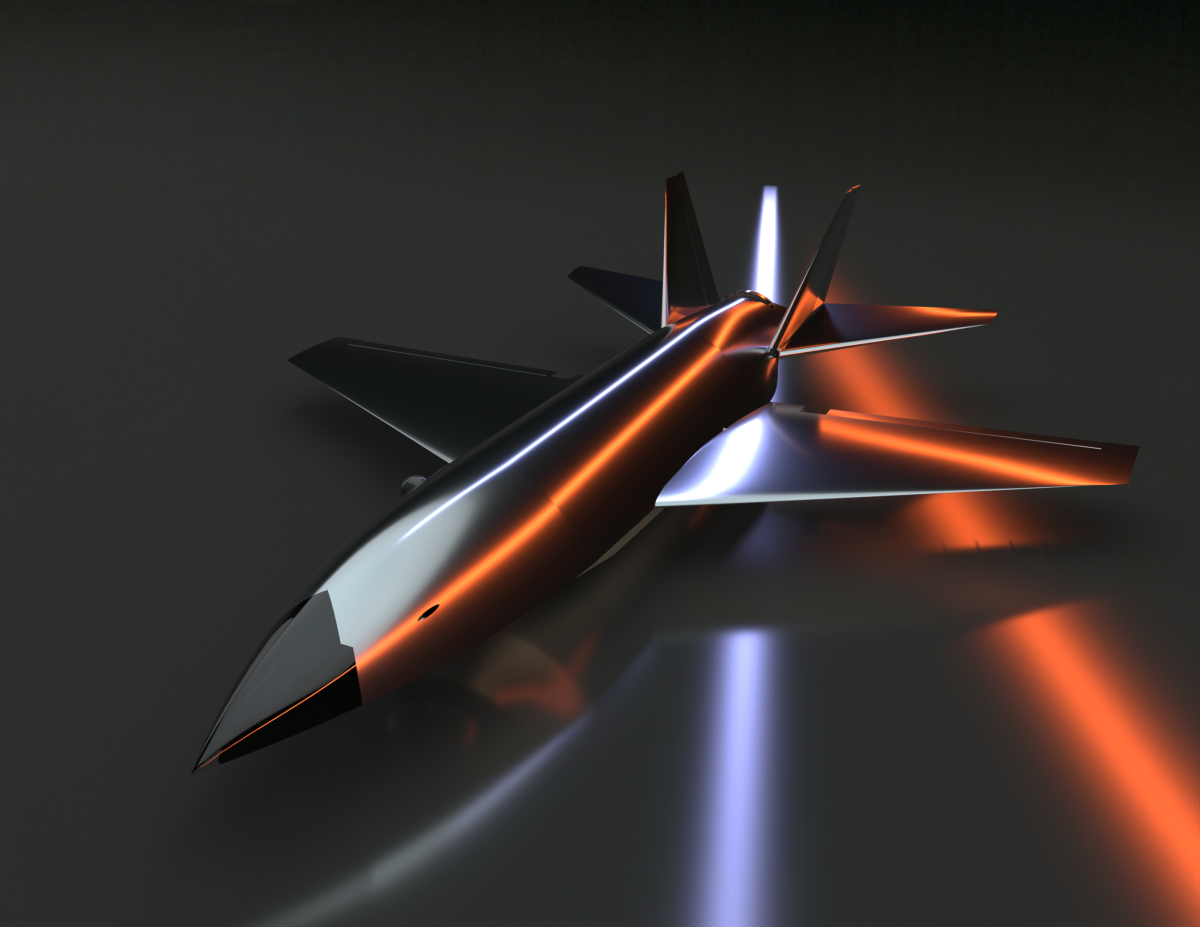

The six-person team conceptualized a highly efficient aircraft for homeland defense.

From left to right: Papa Quainoo, Jacob Labaza, Ethan Das, Dmitri Palmer, Mark Gorrow, Calvin Tomsic and AE Chair Mitchell Walker. View more AE photos from Capstone.

Team Alpha was selected as the Best Aerospace Engineering project at the Spring 2025 Capstone Design Expo for their homeland defense interceptor (HDI) vehicle design, MQ-25 Horsefly. This year, 20 School of Aerospace Engineering teams vied to take home the AE award, while 238 teams from 12 schools competed for Overall Best Project.

Team Alpha, Ethan Das, Mark Gorrow, Jacob Labaza, Dmitri Palmer, Papa Quainoo, and Calvin Tomsic (team lead), based their project on the American Institute of Aeronautics and Astronautics (AIAA) Undergraduate HDI Design Project. This challenge is a significant platform for students to apply their engineering skills to real-world problems.

The United States must be prepared for domestic air attacks. Cruise missiles and hijacked aircraft pose a threat to U.S. airspace. Current interceptor role aircraft in the Department of Defense enterprise, such as the F16 and F22, are expensive to maintain and run, and were not explicitly created for a domestic mission.

Enter MQ-25 Horsefly, a remote-controlled, single-engine, all-weather supersonic HDI vehicle, designed to intercept potential threats to homeland security. Their aircraft was configured with key priorities: cost, efficiency, survivability, replicability, and maintainability. The crewless model can operate up to Mach 1.6 (1227.63 miles per hour). The aircraft’s payload includes an M61A1 20mm cannon and three advanced medium-range air-to-air missiles.

The MQ-25 Horsefly is uncrewed and the estimated annual cost for operations and maintenance for 1,000 units of their model was $368.9 million (including crew salaries, fuel costs, and maintenance), substantially lower than the crewed units at $1.1 billion. The MQ-25 Horsefly offers a lower annual use rate because pilots can train on simulators.

They came up with the name Horsefly for their interceptor because it is native to North America and has a painful bite for its target. They worked closely with their faculty advisors, Carl Johnson and Neil Weston, to present their progress.

“I want to thank our professors—Carl Johnson and Neil Weston—for their mentorship and guidance throughout this process, and the rest of the team for their hard work and dedication this semester,” Tomsic stated. “This project has been a great opportunity to learn how to approach aircraft design, beginning with a set of mission requirements and ending with a detailed conceptual design.”

MQ-25 Horsefly Rendering

MQ-25 Horsefly Section View

The biggest challenge to the project was the AIAA requirements, which led to extensive investigation and multiple changes.

“There were many iterations, and we spent a lot of time trying to create tools to solve problems conceptually. With over 200 requirements comes over 200 different sets of analyses. Those analyses had to match up with one another. For example, if I change something with the weight and balance of the aircraft, or move the wings back, it will affect the aerodynamic performance,” Tomsic said.

The team put in long hours and loads of work to meet these requirements. They had to go through multiple iterations to get their conceptual design right.

“With this project, we got to dive into different disciplines. The biggest lesson was how to work as a team of people at a high level of engineering. Many engineers are excellent at getting the results, but we often struggle with communicating those results to others, and I think learning how to do that was a great lesson,” Palmer said.

The team worked on the project for one semester at a rigorous pace. They said their favorite part was presenting their hard work at the Capstone Design Expo.

“The Aircraft Design capstone course series is unlike any other class I have taken at Georgia Tech; it was an engaging learning experience that equipped me with engineering skills that I will take with me in my future career,” Tomsic said. “I am proud of the team and excited to see what they do next.”

Related Stories:

Solutions for the Operating Room and CubeSat Navigation Top Spring 2025 Capstone Design Expo

Sometimes the best ideas come from working somewhere no one else is. That certainly was the case for the team judged the best overall project at the Spring 2025 Capstone Design Expo April 22.

Their quick-to-adjust surgical retractor is designed to more easily pull back skin and tissue during head and neck surgeries to allow doctors to access deeper muscles, organs, and other tissues. Current devices require surgical assistants to hold them for hours or the use of cumbersome stands, and they require significant effort to adjust.

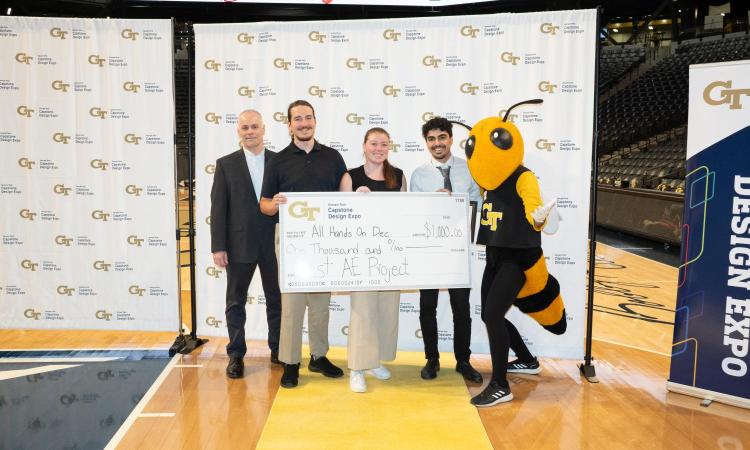

Team All Hands on Dec Takes Top Prize for Best Aerospace Project at the Capstone Design Expo

Team All Hands on Dec is on a mission to uncover the mysteries of the moon. The team won $1,000 and the top honors for Best Aerospace Engineering (AE) project at Georgia Tech’s Fall 2024 Capstone Design Expo held in the McCamish Pavilion on December 2.