About the Yang Aero Maker Space

What is the Yang Aero Maker Space?

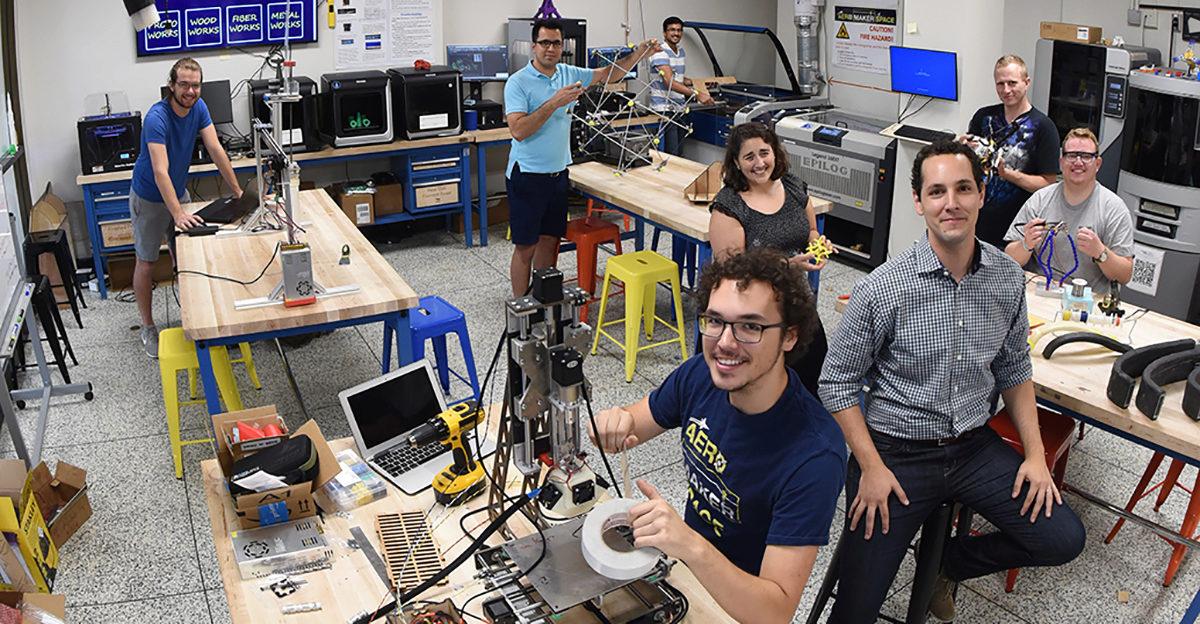

- Quite simply, it's a place where students and faculty can use a variety of equipment to build prototypes that advance their research - and their curiosity. In 2018, the AE School's Aero Maker Space was renamed the Yang Aero Maker Space in honor of the previous School Chair, Dr. Vigor Yang, who supported and funded the creation of the lab.

Who We Are

- It's not like any other lab. The Yang Aero Maker Space is run by specially trained students, Aero Maker Space Mentors, and staff who supervise the safe and proper use of all equipment and train others in the same.

Where We Are Located

- Weber Building | 275 Ferst Dr NW, 2nd Floor, Atlanta, GA 30332

- Located in the street-level foyer of the Weber SST Building, this facility houses prototyping and wood-working equipment.

- Montgomery Knight Building | 270 Ferst Dr, Basement, Atlanta, GA 30332

- The metal-working and composites manufacturing components of the Yang Aero Maker Space are located in the basement of Montgomery Knight.

Contact the AMS Mentors

AMS Supervising Faculty

Equipment

Laser Cutters:

What They Are: The carbon dioxide (CO2) laser machine uses a laser to cut, etch, and engrave materials.

What They Do: The laser cutter cuts and engraves shapes, letters, and other designs. Common examples of materials that can be laser engraved using this machine include: acrylic, anodized aluminum, Corian, Delrin, fabric, glass, leather, laminates, mylar, paper, rubber, stone, textiles, and wood. Common examples of materials that can be laser cut using this machine include: acrylic, cloth, cork, Delrin, foam, laminates and veneer, leather, melamine, paper, plexiglass, plywood, rubber, and solid wood.

3D Printers:

What They Are: A 3D ("three-dimensional") printer employs a standard tessellation language to manufacture three-dimensional solid objects from a digital file by means of an additive processes. 3D printers are commonly used in rapid prototyping.

What They Do: There are a variety of 3D printers in the Aero Maker Space. Some use a plastic filament that starts out on a spool. As the filament is unspooled, it is melted to form the final product. Other printers use an ultra violet (UV) laser beam that scans the surface of a resin and selectively hardens the material. It then corresponds to a cross section of the product, building the 3D part from the bottom to the top. The required supports for overhangs and cavities are automatically generated, and later manually removed.

Wood Tools:

What They Are: The wood tools in the Aero Maker Space include: saws, drills, a planer, sander, and more.

What They Do: The wood tools available in the Aero Maker Space can cut, sand, knurl, drill, hollow, shape, and finish various types of wood and materials.

Other Tools

What They Are:

- Foam Cutter: A 3D CNC foam cutter that can be used for a wide variety of cutting applications.

- Curing Oven: A large format curing oven manufactures quality composite materials through thermal curing.

- Brother Embroidery Machine: a sewing machine that specialized in embroidery detail and applications.

- Cricut Cutting Machine: a small machine that cuts vinyl and paper for various uses.

What They Do:

- Foam Cutter: They can cut virtually practically anything out of expanded polystyrene – EPS foam and extruded polystyrene – XPS foam. This machine is mostly used to cut wings, letters, logos.

- Curing Oven: The oven can be used for aging, curing, bonding, annealing, drying, baking, and heat treating.

- Brother Embroidery Machine: Adds unique and special stitching that can depict words, images, and designs.

- Cricut Cutting Machine: allows for custom cut vinyl designs and paper designs (stickers).

(text and background only visible when logged in)